Coding & Marking Systems

In today’s industrial landscape, product identification and traceability are crucial. To accomplish this, coding and marking systems are used to apply information, graphics, and alphanumeric content onto a wide variety of surfaces.

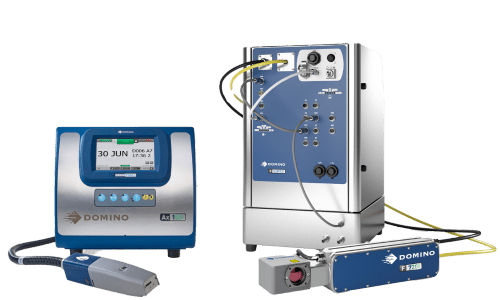

The two leading solutions in this arena are inkjet printing and laser marking. Nimax Tanzania, drawing on years of expertise, delivers options for both approaches, seamlessly integrating them into different manufacturing settings to address all types of operational demands.

Our foremost task is to act as advisors. By analysing your production processes and the latest available technologies, we select the most effective system, install it in your workflow with all the required customizations, and ensure it becomes a fully optimized part of your process—enhancing your line’s overall productivity.

Understanding Coding and Marking Systems

In the realms of B2B and B2C, coding and marking tools are no longer only for compliance—they give consumers accurate data to track individual items.

These systems enable you to apply barcodes, expiry details, production lots, branding, and more to materials such as plastic, glass, paper, metal, or wood. The encoded data is key for monitoring products throughout manufacturing and distribution, for enforcing quality standards, and managing inventory efficiently.

How Do the Two Technologies Differ?

Inkjet Coding and Marking:

- Method: Produces images and text by propelling ink droplets onto the surface to be marked.

- Benefits:

- Lower upfront investment.

- Suitable for rapid throughput applications.

- Supports a diverse palette of inks and colors.

- Compatible with numerous substrates.

Laser Coding and Marking:

- Method: Utilizes concentrated laser light to etch information onto the target surface.

- Benefits:

- Marks are indelible and resist wear.

- Provides extremely clear codes for easy scanning.

- No need for inks or similar supplies.

- Excellent for use on uneven or porous materials.

Today, effective product traceability and labeling are indispensable for safety, process optimization, and meeting regulations. Industrial systems for coding and marking reliably add crucial details—codes, dates, batch numbers, and more—to a broad selection of materials. By thoroughly reviewing your requirements and the criteria above, you can identify the best-performing and most economical marking solution.

How to Choose the Right Technology?

Selecting between inkjet and laser marking depends on a variety of criteria, such as:

- Product characteristics

- Nature of the marking surface

- Details to be printed

- Line production speed

- Budgetary constraints

Each method presents unique strengths and potential limitations. The ultimate decision is shaped by the individual requirements of your business. It is vital to assess these factors carefully to ensure you implement the ideal system.

Marking Solutions for All Industries

Inkjet coding and marking devices offer the broadest versatility among available print technologies, largely due to the extensive selection of inks—ranging from fast-drying to pigmented to food-grade, perfect for food sector packaging. Laser coding and marking tools, by contrast, are particularly suited for sectors running high-speed lines and marking large volumes.

Industrial marking systems must be intuitive, and at nimax Tanzania we focus on your ease-of-use: our systems are built to simplify every stage of your workflow. User-centric controls let you operate your production line confidently and efficiently. Intuitive control panels minimize mistakes, and changing inks or other consumables can be done quickly and hygienically, usually without halting production.

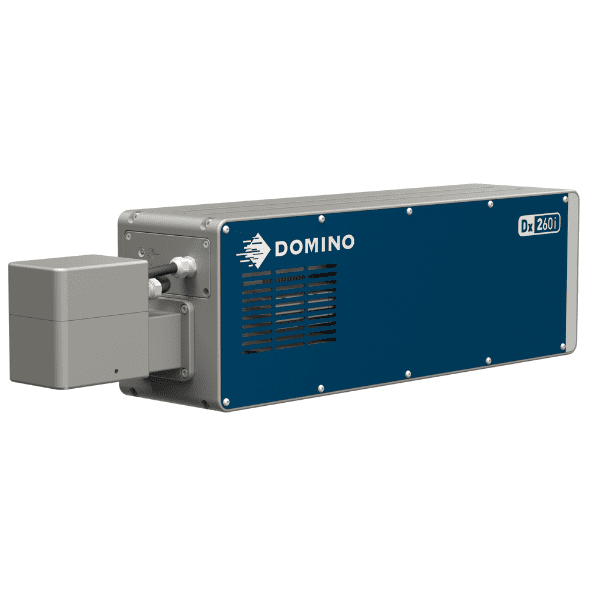

Domino Gx350i

This thermal inkjet printer delivers intricate code printing for robust tracking and authentication.